Seed Production / Quality

Seed production know-how is crucial to successful commercial development of hybrids. Hybrid barley seeds are not just “seeds”. They are high tech products. After the seeds are harvested, they are tested in certified seed quality labs. Only best seeds lots are chosen. Finally, seeds are sorted, treated and bagged at the seed processing plant, ready to be sown.

Year by year we are increasing our knowledge and optimizing our seed processing chains to provide the best quality hybrid barley seeds to our customers all over Europe.

Both breeding and seed production of hybrid varieties is significantly more complex than of conventional varieties. For that reason, seed processing takes place only with well experienced multipliers and selected production companies in France. In addition, the production fields are followed by production engineers of ASUR during the hole season. To avoid loss of seeds, production field are spread in all over France. Our partners are using an innovative storage technology TAMIA PACK which facilitates stock management and prevents seed quality of the stock. These factors guarantee a high level of seed quality and ensures seed availability for the farmers. As hybrid seed is produced by cross-pollinated plants it has to be produced anew every year.

Seed production is splitted in 2 major parts:

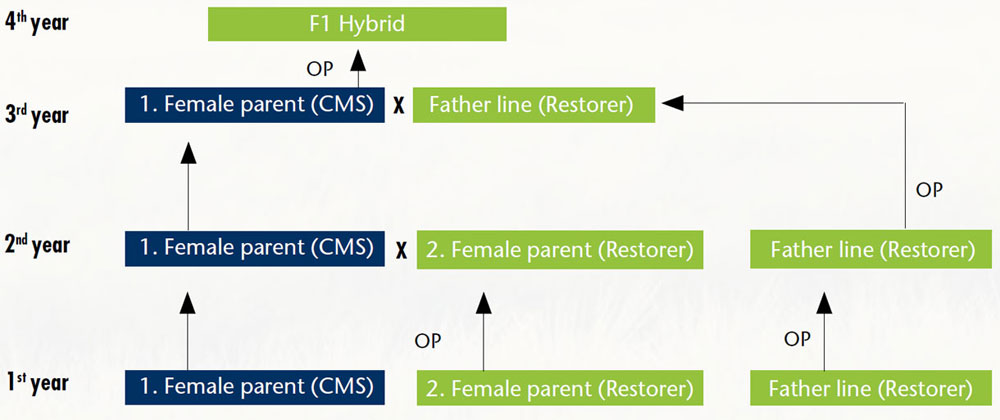

Seed Production Scheme

1. Parental line seed production

Each hybrid consists of 3 hereditary components, 2 females and 1 male, which need to be maintained. The female line (seed parent) consists of a male-sterile line as well as male-fertile line (maintainer line). For propagation both are planted in alternating stripes. The father line (pollen parent) is fertile. No maintainer needed.

2. Certified F1 hybrid seed production

Production of certified F1 hybridseeds, sterile female line is crossedwith the fertile male parent. Hybrid barley seeds could be produced in two different production systems: in strips or in a blend.

These two methods are different in case of costs and quality of the harvested seeds.

Seed suppliers of SAATEN-UNION are using both technologies. The combination of both methods leads to a high and stable hybridisation rate as well as reduced seed costs.

To avoid contamination, the production fields are separated from the other barley production fields. In France, the harvest season starts in July. Afterwards, seeds are proceeded and shipped to the countries all over the EU.

F1 Hybrid Seed Production Methods

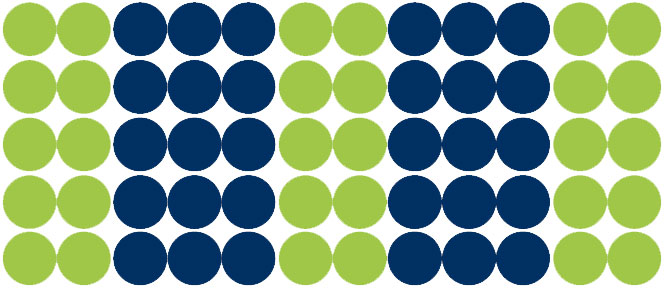

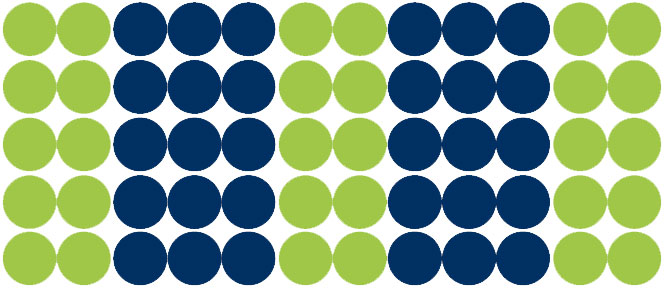

Strip method

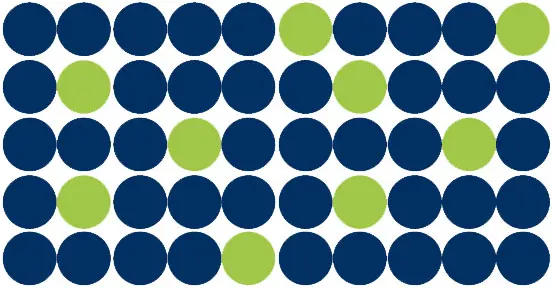

Blend method

Strip method

Blend method

In order to ensure high yields of our customers SAATEN-UNION is paying attention on seed quality testing. Therefore, hybrid barley seeds are underlying numerous laboratory tests before it can go on sale.

1. Germination rate

Germination rate describes the percentage of seeds that produced a normal seedling under regulated laboratory conditions. SAATEN-UNION hybrid barley seeds are tested according to the official seed testing rules. All commercial hybrid barley lots should have a minimum germination rate of 92 %. Due to the great experience and high standards of our partnersin seed production, germination rates of 95 % and higher are achievable.

2. Hybridisation rate

Hybridisation rate explains the percentage of hybrid seeds from the total seeds which are harvested. F1 seeds are produced by using basic seeds of the female and male parental lines. The female seed do-nor line is 100 % sterile. The sterility is tested already on the basic seed level. After cross pollination, the grain harvested from the female parent forms the hybridseed. The hybridization rate for hybrid barley is regulated by the EU law. The standard level is 85 %. The remaining 15 % are seeds of the fertile pollen parent. Higher hybridisation rates are reachable, especially in if the seeds are produced in stripes.

3. Seed purity

Seed purity refers to cleanliness of the seed. Commercial seeds, which are sold to the customers, should be pure homogeneous and free from inert matter, other crop seed and weed seed. Hybrid barley seeds are proceeding by using several different sorters including an optical sorter. It leads to high purity rate (>98 %).

4. Seed treatment: two different standard seed treatments Vibrance Gold

Fungicide with Sedaxane 50 g/L (pyrazole/SDHI), Fludioxonil 25 g/L, Difenoconazole 25g/L (triazole), effective against fusarium in soils at early stages, and rhizoctone, and assure a good implantation. With this seed treatment, we can avoid di-seases when sowing after a cereal. Langis – Insecticide containing cypermethrin 300 g/l (pyrethres), protection of cereals, which had maize or grassland as a preceding crop, against wheat bulb fly and wireworms that cause feeding damages on seedlings and tillers.

The high genetic value of Hybrid Wheat and Hybrid Barley means improving the level of seed processing. The coating agent

Silver-Coat®, a microporous film applied to the surface of the seed, improves coverage and uniformity of the seed treatment as well as grain flow in the drill.

The bright, silver colour of Silver-Coat®, has the additional advantage of tracking the seeds in the furrow. Dosing and choice of coating products are reviewed regularly to optimise seed coverage and limit the risk of dust emissions as much as possible. Untreated seeds can be also delivered.

5. Bostimulant seed treatment

Biostimulats used as seed treatment becomes more and more popular. For the moment we are not offering seeds treated with such a substance, but we are working on a project. Our goal is to test and to figure out the best treatment which we can offer to our customers.

6. Bagging types

We can propose different kind of bagging. In Hybrid barley we are dealing with units of 500.000 grains – the standard bags. Further, we are offering also big bags with 12 million kernels.

industrial process for vacuumpreservation of seeds and grain

- Controlled storage: Preserving quality; germination level stay on a high level.

- Securing stocks without insecticide treatments: Performance is proven by five years of use on more than 6500 tons.

Advantages for the farmers: High level of seed quality regarding germination rate and low risk of contamination by insects.

Innovative storage technology at ASUR Plant Breeding

TAMIA PACK technology is a newly created subsidiary of ASUR PB. TAMIA PACK offers the SAFET‘HY® industrial process for all seeds including hybrid and non-hybrid cereals. All seed stocks at ASUR are now stored using this process.

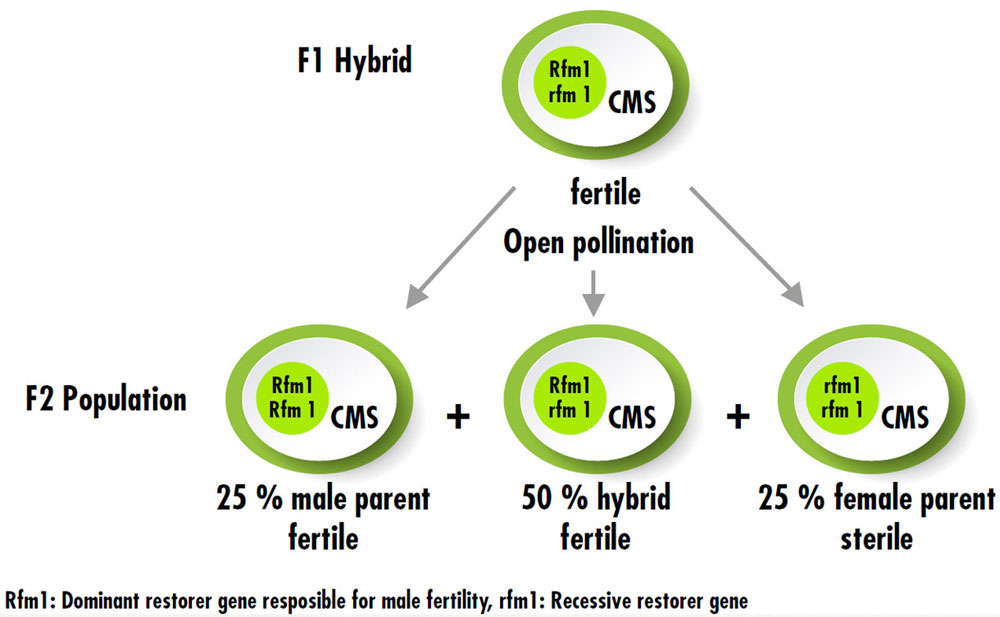

According to European law it is forbidden to sell or to grow farm saved seed of CMS hybrid barley. Furthermore, reproduction of hybrid barley seed results in heterogenous fields as well as severe reductions in yield.

A conventional variety is selected from a cross in eight to ten generations, with pollination taking place via the natural mechanism of self-pollination. Throughout the process „countless“ genetically different strains segregate from one cross of which only the „best“ is developed into a variety. Thus, the conventional variety is based on genetic „equality“, which means if reproduced largely identical offspring with hardly any changes in performance characteristics are produced.

Segregation of F1 CMS Hybrid

On the other hand the hybrid variety is only a recently created cross (AxB)xC. It is a combination of three different parental lines. In this state the so-called heterosis effect is expected. Heterosis of a cross is defined as superior performance surpassing the average of its parents. According to the law of segregation (Mendel‘s laws of inheritance) hybrid reproduction inevitably leads to a genotypic segregation ratio of 1:2:1. The heterosis effect is lost, performance decreases.

Certified F1 seeds have following advantages:

- Newest high performing genetics

- High level of hybridization (min. 85 %)

- High level of germination rate

- High level of purity

- High quality seed treatment

- Less workload